Company Spotlight: Domestic Manufacturer Renova

Sometimes when a scrappy, innovative company loses its founder, the business continues on — but without some of the forward-thinking practices and creative problem-solving that made it unique. This was not the case with Renova Lighting Systems, a domestic lighting manufacturer headquartered in Rhode Island that began with fluorescent technology before transitioning to LED.

“Renova Lighting was founded in 1998 by Rick Edwards and a group of visionary business partners with a mission to pioneer energy-efficient lighting solutions across the United States,” recounts Jessica Mularski, president and owner. “Tragically, Rick passed away in 2022, leaving behind an incredible legacy of quality craftsmanship and forward-thinking design. On June 1, 2023, my husband Jeremy and I acquired Renova and have been honored to steward its future.”

The Mularskis bring a lot to the table when it came to continuing Renova’s success and momentum in the commercial lighting industry. Jeremy, Renova’s COO, has more than 20 years of experience in the industry as an engineer and as an operations leader, while Jessica’s career is rooted in education and marketing.

“Between his deep technical background and my experience in business, leadership, and communications, we realized we had the right mix of skills to take Renova to the next level,” Jessica explains.

“I spent 17 years teaching, primarily in Communications, Graphic Design, Marketing, Computer Science, and Photography,” she notes. “I had originally planned to go into business [at a PR firm], but ultimately shifted paths and earned my first Master’s degree in Education. My love for business never really went away. Even while teaching, I stayed engaged in small entrepreneurial projects and continued to learn about marketing, technology, and leadership.”

When the opportunity came along to acquire Renova Lighting Systems, Jessica says it felt like a perfect fit.

“Because of my background, stepping into a sales and marketing leadership role came naturally. I hold a sixth-year degree in Educational Leadership, which focused heavily on management and organizational development, so I was eager to apply those skills to running and growing a business,” Jessica says. “My time in the public sector also gave me valuable experience navigating government systems, grant writing, and compliance — all of which have been extremely helpful as we’ve expanded Renova’s work with federal and state projects.”

While shifting careers from education and marketing into the more technical field of lighting might seem daunting, the process has been rather seamless. “The transition into manufacturing and the lighting industry has been both exciting and deeply rewarding. I’ve always been a lifelong learner, so immersing myself in the complexities of lighting — from engineering and design to construction, bidding, and distribution — has been fascinating. It’s truly a field where technology and creativity meet,” she comments.

Jessica’s interpersonal skills as a teacher and Jeremy’s lighting knowledge have helped maintain Renova’s reputation for being a fulfilling place to work for employees. “I’m incredibly fortunate to work alongside Jeremy and our talented team here at Renova. Together, we’re constantly striving to blend technical innovation with a human-centered approach to design and service,” she comments. “For me, it’s been the ultimate opportunity to bring together everything I love about learning, leadership, and innovation — and turn it into something that makes a real impact. As a family-led operation, we’re committed to honoring [Renova’s] heritage while infusing our own passion for ethical manufacturing and customer-centric innovation.”

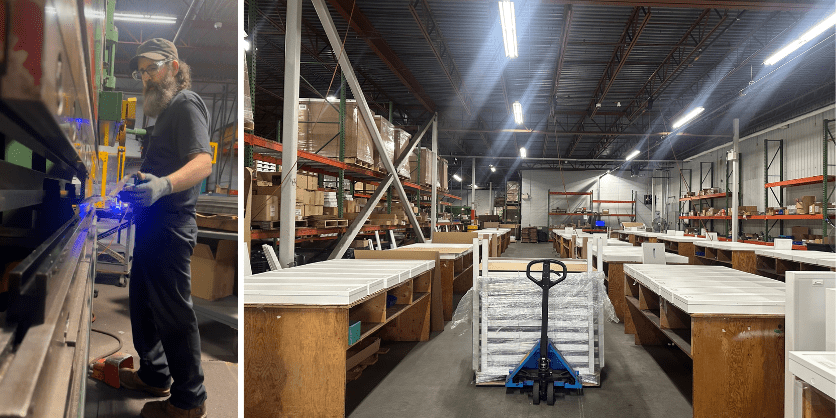

Renova specializes in customized LED lighting products for commercial, architectural, and industrial applications. Everything is produced in-house at the company’s Rhode Island facility — from design and engineering to fabricating, assembling, and performing quality control before each product is shipped out.

Renova recently achieved yet another unique milestone: certification as a Woman-Owned Small Business (WOSB) and Woman Business Enterprise (WBE), in addition to its Minority Business Enterprise (MBE) status.

“This isn’t just a formality; it’s a reflection of our transition to new leadership under my guidance as a woman entrepreneur, building on 25+ years of established excellence. This certification is profoundly important to us because it aligns with our core values of inclusivity and opportunity, opening doors to government set-asides and diverse supplier programs that level the playing field for small, innovative manufacturers like ours,” Jessica states.

“For our manufacturer reps, lighting agents, and distributors, [these certifications] mean enhanced marketability. They can position Renova as a strategic partner for projects requiring diversity compliance — giving them a competitive edge in bids,” Jessica explains. “Customers benefit, too, as specifiers and end-users gain access to high-quality, compliant products that help meet regulatory goals without compromising on performance. It fosters trust, signaling our commitment to ethical practices and community impact. Ultimately, it’s a win-win that strengthens partnerships and drives sustainable growth.”

In a tariff-laden world, Renova’s status as a domestic manufacturer is yet another advantage. “We don’t just assemble — we fabricate sheet metal in-house, allowing us to tweak everything from sizes and gauges to controls, paint finishes, lumen packages, color temperatures (CCTs), and CRI values to meet precise project demands,” Jessica recounts. “As a certified WBE/WOSB, we’re primed for set-aside opportunities, and our products fully comply with the Buy American Act (BAA), Build America Buy America Act (BABAA), and Trade Agreements Act (TAA). We respond to all inquiries within 24 hours, provide tailored lighting plans to streamline project design, and offer on-site support — visiting customers to take measurements and provide expert guidance when needed,” she states. “What truly sets us apart is our white-glove service. From concept to delivery, our team handles every step, ensuring American-made quality that’s resilient to supply chain disruptions.”

Renova’s MBE/WBE status helps general contractors fulfill diversity requirements, freeing up budget flexibility elsewhere, while the “Made in America” aspect appeals to clients who are prioritizing ethical sourcing and reliability. “We’ve seen this play out in bids for public sector work, where compliance gives us an edge,” she adds.

Telling the Renova Story

When it comes to ways that reps can convey the advantages of working with Renova, Jessica points to case studies that show how custom fabrication reduced lead times by 30% on a hospital retrofit, or how BAA compliance streamlined approvals for a municipal park upgrade. “Distributors could also bundle training sessions on the human-centric benefits of the Sunlike chip we offer, educating specifiers on ROI beyond lumens — like enhanced occupant well-being. Specifiers could integrate our differentiators into early RFPs, using tools like our online configurator for quick custom mocks.”

Among the notable projects that Renova has supplied fixtures for include police precincts and hospital projects as well as offices, classrooms, and athletic areas at Ivy League-level institutions.

According to Jessica, Renova often gets called in to “help meet budget demands for tailored efficiency, the need for customized sizing, diversity procurement goals, or post-bid discoveries that imported products are impractical due to tariffs, supply chain delays, or compliance issues. Our sweet spot is mid-to-large-scale public or institutional projects (e.g., $100K+ lighting budgets) in sectors like government offices, military facilities, healthcare, education, or municipal infrastructure — especially in the Northeast, but scalable nationwide.”

Benefits to Distributors

Renova’s ability to cross-specify fixtures on existing specifications saves distributors time by providing compatible alternatives without redesigns. “We retrofit both our own and other manufacturers’ fixtures, ensuring seamless integration with existing systems. We also create or source solutions for project-specific challenges, adjusting sizes, 20-inch gauge flanges, or post-paint options to fit existing profiles, reducing material and labor costs. Our below-ceiling replacements eliminate expensive above-ceiling work, enhancing cost-effectiveness,” she explains.

On the Horizon for 2026

Jessica foresees opportunities in federal expansions and smart-building retrofits. “We’re rolling out our innovative Sunlike chip this year — offering 98 CRI, Rf 96-98, Rg 99-101, and 132 lm/W in a cost-effective, violet-free package that accelerates natural-light adoption without premium pricing,” she comments. “By 2026, we’ll introduce heat-mapping sensors for fixtures, revolutionizing security (e.g., detecting anomalies in active-shooter scenarios) while tying into energy management. We’re investing in R&D for modular, upgradeable platforms to future-proof installs, partnering with reps for specifier education, and scaling our Rhode Island fab for faster customs. It’s an exciting horizon — we’re not just adapting; we’re leading with ethical, American ingenuity.”