How to Protect Your Bottom Line From Rising Material Costs

February 20, 2022

February 20, 2022

Few things can ruin a business faster than angry customers and projects that take too long to be completed. The past two years have been fraught with delayed containers, product shortages, and price hikes — all of which have eroded profit margins.

Dave Burleigh and Ed Hauck of home building industry specialist Shinn Consulting shared their insights for proactively easing some of those pain points while managing customer expectations.

“We’ve been getting calls from our customers for the past year and a half about supply chain issues,” explained Dave Burleigh, Estimating Consultant. “It started with lumber and now it’s bled into everything else, with builders asking, ‘Hey, my trade partner can no longer provide this, what should I do?’”

Ed Hauck, Senior Consultant, concurred, adding, “There pretty much hasn’t been a cost code that hasn’t been affected. It’s hard to change materials, and we’re being forced to find alternatives on almost a daily basis.” The key to successfully surviving today’s volatile business environment is to have a process in place for evaluating the true cost of making a change in materials — because sometimes what sounds like an easy switch is actually costing you money.

Burleigh detailed what such a process should look like when you’re changing materials or specifications. “It’s never as easy as the trade partner saying, ‘I have to go from Material A to Material B and it’s a $10 a unit difference,’” he said. “There’s a lot of cost beyond that number.”

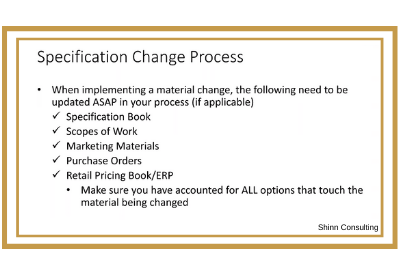

Burleigh gave the real-life example of a market that no longer has access to cultured marble vanity countertops. “The first thing to do – when we’re going to make a change to a specification because something is either on backorder or no longer available – is to make sure we’re accounting for everything that needs to happen. It’s not just signing the contract with that trade partner to switch from the cultured marble top to granite, I need to go back and make sure my specification book is correct.”

Do the Homework

“My scope of work has to be altered now that we’re going from cultured marble to granite — and it needs to be spelled out,” Burleigh explained. “If it’s a material that’s called out on my marketing materials or included features, I need to update them. I have to go back to the purchase orders, depending on when this change takes effect. In this instance, it was an immediate impact. It wasn’t a case of, ‘We’re going to get through the houses that are already sold [and then switch]…’ We had to go back to existing purchase orders and make those changes. Therefore, we need a process in place to make sure we’ve got those purchase orders accounted for,” he stated. “Then we had to look at our Retail Pricing Book. Again, it wasn’t as simple as [one swap] because I had a lot of structural options affected by that one change. Any optional bathrooms, finished basements, anything that touched those countertops, I needed to make sure that all of that pricing was updated on the retail side so I wasn’t prolonging the impact of that financial change.”

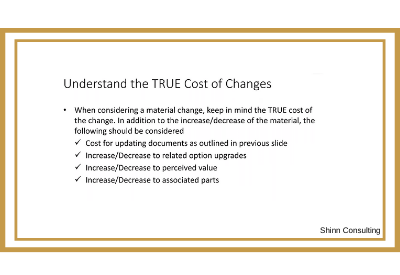

This attention to detail is key. “We want to understand the true cost of the change. I don’t only want to know the material cost difference of going from cultured marble to granite, I need to know how it affects me overall,” Burleigh remarked.

Don’t forget to calculate the cost of updating all the paperwork. “That’s not free, that is time that has to be spent changing all those purchase orders and changing all the bids and the scopes of work. There is an additional cost incurred by us to get that program realigned based on that change,” he commented.

Next, check what that change did to any option upgrades. Did it change how your options work? Are you going to see a decrease in upgrades because of this, or are you going to see an increase in upgrades? Does that change affect your business plan?

“I want to look at what [that change] does to perceived value,” Burleigh said. “If I make this change, does that make me a more attractive builder to potential buyers, does it make me less attractive, and what does it do to my reputation based on that change?”

The last step is to assess whether anything else needs to change because of the switch. “In this particular case, instead of the cultured marble vanity with the integrated bowl, I’m going to have granite. And it’s not just the granite, but now I need to have an undermount sink — and that starts to affect my options. I need to dig in and figure out what this costs me. It’s not just a $17 per square foot in countertop difference, there are other areas that are going to be affected.

Dig Deeper

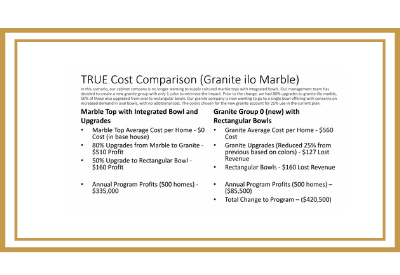

“In the example of the cabinet company no longer able to supply cultured marble tops with integrated bowls, our management team decided to create a new granite group with only one color,” Burleigh stated. “That way, we could get ultra-competitive on the bid price. When we started to dig in, we saw that 80 percent of our buyers were upgrading from granite to marble. I need to look at what’s going to happen to my options and beyond that.

“So, in my granite program, I also offer the ability to go from an oval sink to rectangular,” Burleigh noted. “Through the process of negotiation, the granite company said, ‘We’re running low on oval bowls, how about we give you the rectangular bowls at no additional cost?’ Which sounded really good right out of the gate, except we saw that we had been getting 25-percent upgrades for people going from oval to rectangular, so now I’m going to lose a little more of my revenue.”

In the original program, the cultured marble top with an integrated bowl did not cost anything additional. “I already had that cost factored into my base house,” Burleigh explained. “But on a typical home, with 80 percent of upgrades going to granite – even to a granite level one, which is my first step – I had a profit of $560 per house to make those changes. And in 50 percent of those, I was able to get $160 profit from upgrading to the rectangular bowl. So, if I were building 500 homes a year, going from cultured marble to the granite and then touching the bowl, I’d be averaging $335,000 in profit dollars per year off that program. But, when I compare it with going to a granite group zero with the rectangular bowls, my average cost increased by $560 per house. On top of that, we found that the 25 percent of buyers who were upgrading to granite were using the color we selected as our new base color — so I’m losing an additional $127 in revenue from that. Then, in my bowls, I’m losing [the upgrade] completely by going to the rectangular as the base, so that’s another $160 I’m knocking off the home,” he confirmed.

Performing this due diligence, while time-consuming, is ultimately important for staying profitable. “When I look at the program as a whole, I’m going from a $335,000 total profit to actually costing me an additional $85,500 to use this program. When I balance those two numbers together, I’m reducing my profitability by $420,500 by making this one change,” Burleigh stated. “This really highlights the fact that if we had left it at the original idea of going from Option A (cultured marble) to Option B (granite) and were only looking at that $560 per house, I might have thought that change was palatable. But as we dug in deeper to see what it was going to do to our total profitability, we determined that it wasn’t palatable at all because it was a much higher number than it appeared to be at first glance.”

Research Alternatives

Once it was determined that the “simple switch” was ultimately not such a great idea, it’s time to research alternatives.

“Anytime I get a phone call like this, there are certain things I want to find out to see what else I could do that won’t be as big of an impact,” Burleigh commented. “First, I want to talk with people in my builder group and see if anybody else is running into this problem. If so, what did they do and what was their final outcome? I’d like to get a couple of different views.”

As counter-intuitive as it may seem, Burleigh suggested checking with competitors. “We did that in this case with the cultured marble vanity tops,” he explained. “We checked what other builders in the market were doing. In this case, we found everyone was going to granite, so that kept us on a level playing field. We also spoke to other vendors and trades. This particular builder is sole-sourced for cabinets, which means they were sole-sourced for cultured marble. They’re also sole-sourced for granite. We reached out and talked to other cabinet companies and other countertop companies to discover whether this was a business decision or a market decision. Since cultured marble in that market was disappearing completely, finding an alternative way to get cultured marble was not an option,” he said. “We also wanted to know the long-term outcome on this market constraint. In this case, cultured marble was disappearing for good; however, had we determined the shortage was temporary and would last six months, that will change my viewpoint. I might be willing to take that bigger jump out of the gate if I’m only doing it for 250 – which is half – of my 500 homes. In this case, the answer was that this would be a permanent change (lasting over a year). As such, I had to make sure I was thinking long-term when looking at those 500 homes per year and looking out three to five years to determine what it’s going to cost me.”

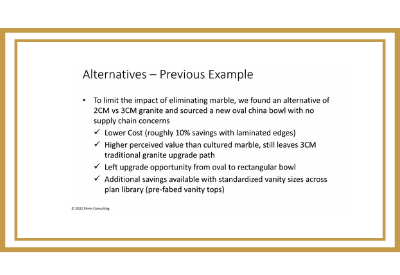

Burleigh shared that another countertop vendor suggested doing 2CM granite with laminated edges instead of the more upscale 3CM. “We dug in and started looking at that option and found that we’d save about 10 percent,” he recounted. “Instead of paying an additional $17 a square foot with the switch from cultured marble to granite, I can subtract $1.70 from that and limit the impact a little bit. We found that granite still has a higher perceived value, and even though we’re using the thinner granite, buyers still feel having granite instead of cultured marble was an improvement,” he said, adding, “I was still giving the buyers a better product while protecting my profit a little bit.”

Even better, buyers in that marketplace were upgrading to 3CM. “There were some buyers who didn’t like the look of the thin edge, so they were willing to pay to upgrade,” Burleigh explained. “I was able to have less of an impact on my option structure by going from a 2CM and moving into my normal 3CM product line and being able to offer all of the same upgrades. As we dug into that, we also found that we could source an additional oval bowl. It wasn’t that oval bowls were a problem for our granite company, it was the specific bowl they were buying that was the problem. They did have other opportunities that we were able to work through to find an oval bowl that they could source at the level that they needed and at a price point that was competitive to what we had before. That allowed me to continue to offer that easy upgrade to the rectangular bowl, which was a really good increase to my program overall from a financial standpoint.”

Burleigh’s cost analysis wasn’t finished yet. Switching to 2CM granite only saved 10 percent because they offered many vanity sizes. “In a whole bath situation, I offered anything from a 30-inch vanity to a 96-inch vanity, depending on the plan,” he explained. “The feedback we got from the countertop company was, ‘If you could streamline and give us three to four standard size vanities, then we can order that 2CM in prefab and save an additional 25 percent. That’s a process we’re going through today, to circle architecture and design back in to find out if we can limit those sizes so we can get that program back to being a good money generator for us overall.”

Be a Better Negotiator

Ed Hauck provided additional insight on the project. “Dave worked heavily in this process with suppliers and manufacturers; they were huge in helping us navigate through this,” he said. “One of the things we have to think about is that there are roughly 35 trades per home and every single one of them has threats right now, threats like this tiny instance of changing the tops of materials. We have to be very adept at making sure we can reach out to suppliers and manufacturers — and don’t forget, at some point we’re negotiating even simple little things like I-joists. Say one I-joist size is no longer available, well they’re going to ship the next size up and charge us. Can we negotiate out of that? The countertop switch is a relatively simple supply chain issue, but look at how much money is involved,” he stated. Although builders are constantly hit with changes and increases in materials, Hauck said there are 20 different things that can be negotiated in the process.

One pitfall that can hinder builders’ profitability is their preference for sole sourcing. “Builders are notorious for falling in love and not wanting to break up,” Hauck joked. “I have to be able to talk to [another vendor] and have that hard conversation once in a while with my current vendor that, ‘Hey, I talked to so-and-so and I might need to make a change.’ In this case, they were going to sole source all of the kitchen product from somebody – which makes sense from ease of use – but I had to consider a different granite supplier.”

What it comes down to, according to Hauck, is examining the whole process and evaluating the cost. One thing builders don’t think about often is that lost revenue from all those upgrades, which can be huge at times. “I want to put all that together, sit back, and think about how many different buckets we need to touch in negotiating. Just because I can’t get the product I wanted doesn’t mean I’m done. Think about all the different pieces you can dig into and negotiate. I want to find the lowest price and most guaranteed product I can find,” he stated. When pricing out alternatives, Hauck advised being diligent in making sure the substitution is an equal, if not better, product.

“The other thing I want to bring up is size. Every time I have a different size, I have a different SKU,” Hauck commented. “Start looking at standardized sizes. More often than not, I can jump up a size – if I have the room – and can get it for less money. I want to know what those SKUs are, the list prices, and the multipliers on these different vanity sizes. Then I want to know what those vanity top sizes are. There are a lot of little things like this x 35 trades,” he said. “Sometimes on top of a supply issue, there’s also an offering issue. If I have 40 plans in my library, but I’m offering 200 window SKUs based on size and colors, those are things I can look at from a design standpoint and streamline to put myself in a better buying position. See what your competitors are doing. If I’m doing 3060 windows, but my competitors are doing 3050s and they don’t seem to be having the same problem getting them, I’d look at whether I should be doing 3050s. I’d want to start getting rid of those SKUs and put myself and my trade partner/distributor in a better position to not have to worry about carrying all that for me. Part of that conversation is asking my manufacturers and distributors, ‘What can I get ahold of? What are the SKUs you’re having the least amount of problems getting ahold of because I might want to start using those.’ I’d rather hedge my bets and not have those problems any longer.”

“The other thing I want to bring up is size. Every time I have a different size, I have a different SKU,” Hauck commented. “Start looking at standardized sizes. More often than not, I can jump up a size – if I have the room – and can get it for less money. I want to know what those SKUs are, the list prices, and the multipliers on these different vanity sizes. Then I want to know what those vanity top sizes are. There are a lot of little things like this x 35 trades,” he said. “Sometimes on top of a supply issue, there’s also an offering issue. If I have 40 plans in my library, but I’m offering 200 window SKUs based on size and colors, those are things I can look at from a design standpoint and streamline to put myself in a better buying position. See what your competitors are doing. If I’m doing 3060 windows, but my competitors are doing 3050s and they don’t seem to be having the same problem getting them, I’d look at whether I should be doing 3050s. I’d want to start getting rid of those SKUs and put myself and my trade partner/distributor in a better position to not have to worry about carrying all that for me. Part of that conversation is asking my manufacturers and distributors, ‘What can I get ahold of? What are the SKUs you’re having the least amount of problems getting ahold of because I might want to start using those.’ I’d rather hedge my bets and not have those problems any longer.”

Both Hauck and Burleigh stressed the importance of being thorough. “As soon as you know about a change, you have to bring in the sales and marketing team. Too often we’re so busy in Purchasing that we forget the other departments we need to work with,” Hauck stated. “If I’ve just brought in a new product because of a materials change, my sales and marketing and design center teams have to start selling it and making it a positive.”

Finally, it is essential that every change made is noted in your system. Burleigh explained, “You’ll have to change the sales system to recognize a new countertop type, for example, and rebuild all the production data, too. There’s a cost to that. We calculate that out and use it in our negotiations to show that there was a big impact to us to make that change.”