3D Printing: Inside Lighting’s Next Revolution

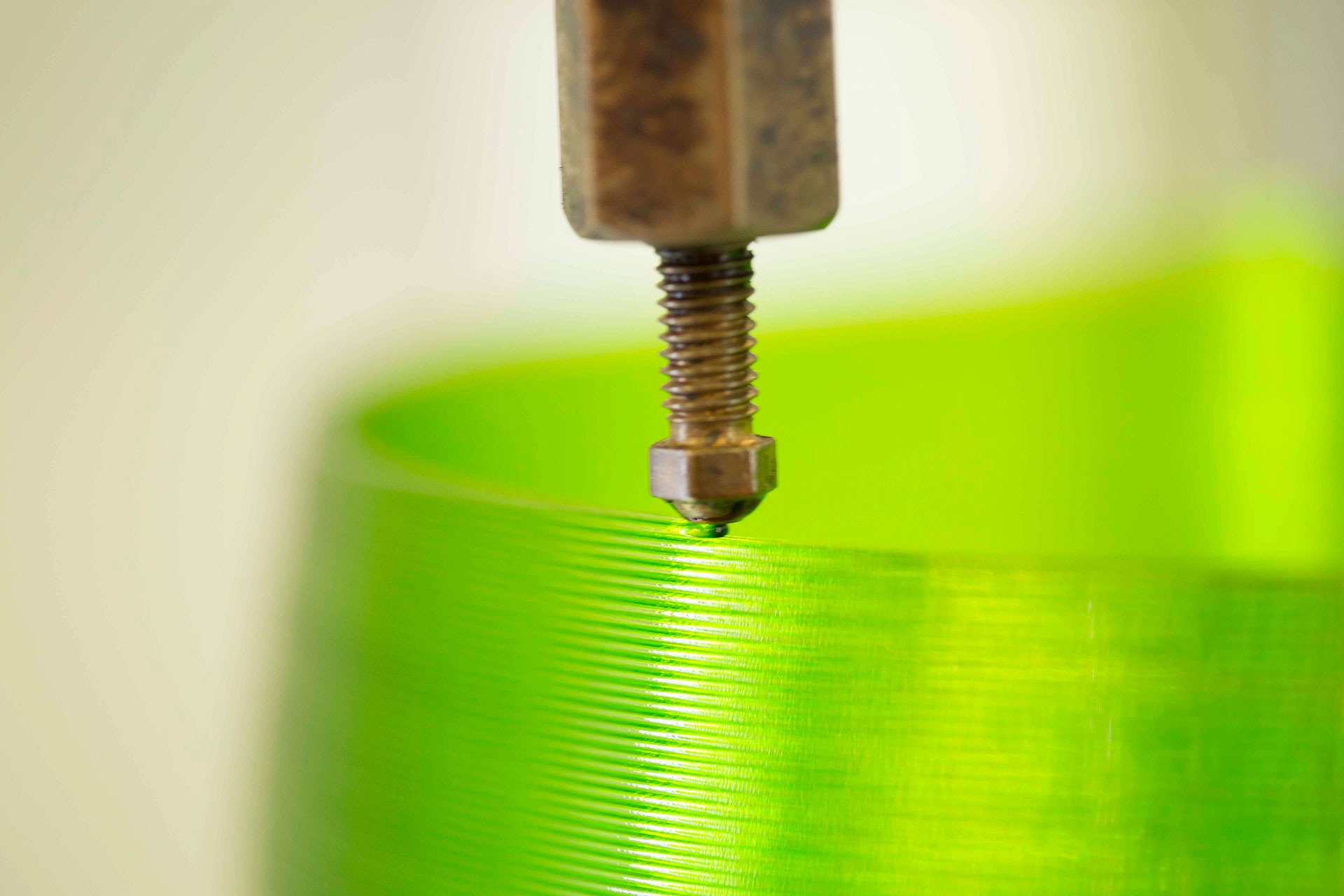

While 3D printing in mass production was once a dream, advancements in the technology have moved it more into the mainstream. The technique, which is also referred to as additive manufacturing, has rapidly evolved from a niche prototyping tool into a transformative production method for many sectors, including the lighting industry.

As manufacturers confront supply‑chain volatility, sustainability mandates and growing demand for customization, 3D printing is emerging as one of the most consequential technologies reshaping how luminaires are designed, produced and delivered.

From Rapid Prototyping to Full‑Scale Production

For years, 3D printing was primarily used to accelerate early‑stage design, enabling engineers to iterate on optics, housings and mechanical components in hours rather than weeks. That value remains, but the technology’s role has expanded significantly.

Advances in materials and print resolution now allow manufacturers to produce durable, end‑use components suitable for commercial lighting applications. Signify, a global leader in lighting, has been at the forefront of this shift. The company’s 3D‑printed lighting program—originally developed under Philips Lighting—now produces luminaires at an industrial scale using recyclable polycarbonate materials.

This evolution is especially impactful in architectural and decorative lighting, where complex geometries and low‑volume SKUs often make traditional molding or metal fabrication cost‑prohibitive. With additive manufacturing, complexity is essentially free. A fixture with intricate latticework or organic forms takes no more time or tooling than a simple shape.

Customization at Scale

One of the most compelling advantages of 3D printing is its ability to deliver customization without the traditional penalties of custom manufacturing. Designers can tailor fixture dimensions, textures, optics and colors to meet project‑specific needs while maintaining predictable lead times.

Signify’s 3D‑printed portfolio—including its Lightolier and Genlyte Solutions offerings—highlights this capability. Customers can modify colors, textures and shapes, and even create bespoke luminaires that are printed on demand.

This flexibility is equally attractive to hospitality, retail and workplace environments, where brand identity and experiential design are increasingly important. A retailer, for example, can adjust fixture sizes or beam angles to match store layouts without retooling.

For manufacturers, this shift opens new business models. Instead of forecasting demand and holding inventory, companies can produce fixtures digitally and print them as needed.

Sustainability Gains Across the Lifecycle

Sustainability is another major driver accelerating the adoption of 3D printing in lighting. Additive manufacturing inherently reduces waste because material is deposited only where needed. Signify’s 3D‑printed luminaires are made from recyclable polycarbonate and other sustainable materials, and the company has introduced product lines—such as its 3D‑printed office lighting made from recycled PET—that demonstrate how circular design can scale.

Localized production also reduces transportation emissions. Instead of shipping finished luminaires across continents, manufacturers can distribute digital files to regional print hubs or print directly at the point of installation. This approach aligns with broader industry efforts to reduce embodied carbon and improve circularity.

Acuity Brands: Exploring the Next Frontier

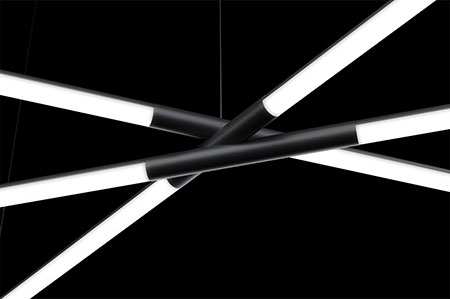

While Acuity Brands is not yet producing mass‑market 3D‑printed luminaires at the scale of Signify, the company is actively exploring additive manufacturing’s potential. Acuity’s A-Light brand introduced Aloft 3D, a system that uses laser‑printed metallic joiners to create customizable linear lighting configurations. These components allow designers to specify unique shapes, angles and optics, which can expand design possibilities.

Acuity has also participated in industry‑wide research initiatives to explore 3D printing’s role in solid‑state lighting and building applications. These efforts signal a growing commitment to integrating additive manufacturing into future product development.

Speed and Supply‑Chain Resilience

The COVID-19 pandemic and several severe weather events over the past decade exposed vulnerabilities in global supply chains, prompting many lighting manufacturers to rethink their production strategies. 3D printing offers a way to mitigate risk by reducing dependence on overseas tooling, long lead times and complex logistics.

In addition, additive manufacturing requires no molds, which means manufacturers can pivot quickly when demand shifts or when components become unavailable. Replacement parts can be printed on demand, extending product lifecycles and improving serviceability.

And while 3D printing often may be perceived as slow, the reality is that it can shrink lead times dramatically. A custom fixture that once required weeks can now be produced in days.

Challenges and Considerations

Despite its promise, 3D printing is not a universal solution for lighting manufacturers. Material limitations remain, particularly for high‑temperature environments or applications requiring heavy‑duty structural components. Surface finishes, while improving, may still require post‑processing to meet certain aesthetic expectations.

There are also specific risks that come with 3D printing with metal powders, which can cause combustion, toxicity or hazardous fumes if not handled properly. High porosity and low density in the finished products are also common problems due to variable conditions during the process, such as temperature or energy flow consistency. These can be overcome, but should be considered when looking to expand the use of additive manufacturing.

Standards and testing protocols are also evolving. Manufacturers must ensure that printed components meet UL, DLC and other regulatory requirements, which can be more complex when materials and geometries differ from traditional products.

Finally, scaling production requires thoughtful investment in equipment, training and digital workflows. Additive manufacturing is as much a software challenge as a hardware one, and companies must adapt their design and engineering processes accordingly.

A Transformative Technology for a Changing Industry

As the lighting industry continues to evolve—driven by sustainability goals, design innovation, and the need for supply‑chain resilience—3D printing is poised to play an increasingly central role. Companies like Signify are already demonstrating what large‑scale additive manufacturing can achieve, while others explore hybrid approaches that blend traditional craftsmanship with digital fabrication.

While 3D printing isn’t likely to fully replace conventional manufacturing, it’s already carving out a significant and growing niche. And as the technology continues to evolve, even more opportunities are possible.