Why Specifications Matter: The Hidden Cost of Compromise

By Geoffrey Marlow, President, Marlow Advisory Group

The construction industry has a dirty little secret: the specifications that owners pay thousands of dollars to develop are often treated as suggestions rather than requirements. Specifiers watch their carefully crafted documents get diluted through “equivalent” substitutions. Contractors proudly present value engineering proposals that slash costs while quietly compromising design intent. And somewhere in the middle, the owner – who hired the specifier for their expertise – ends up with a project that delivers less than promised.

This systemic problem particularly affects commercial and industrial lighting and controls, where technology evolves rapidly, budgets compress late in the schedule, and differences between products can be subtle but very significant.

The CSI Structural Trap: Divisions 25 and 26 as Budget Scapegoats

The CSI MasterFormat places integrated automation in Division 25 and electrical systems including lighting in Division 26. This logical organization has inadvertently created a perfect storm for value engineering abuse.

Here’s the reality: These divisions enter the budget conversation late. By the time lighting designers and controls engineers finalize specifications, architectural and structural elements have already consumed significant budget. When cost overruns emerge – and they always do – project managers look downstream for savings. Lighting and controls become the convenient adjustment valve because they haven’t yet been purchased or installed.

This timing isn’t accidental; it’s structural. Lighting and controls systems require completed architectural plans to specify properly. But this necessary sequencing means these systems arrive at the budget table when flexibility has been exhausted elsewhere. The result? Specification integrity gets sacrificed not because lighting and controls weren’t properly specified, but because they’re a late-to-the-table opportunity to reconcile budget reality with design ambition.

When “Equal” Doesn’t Mean Equal

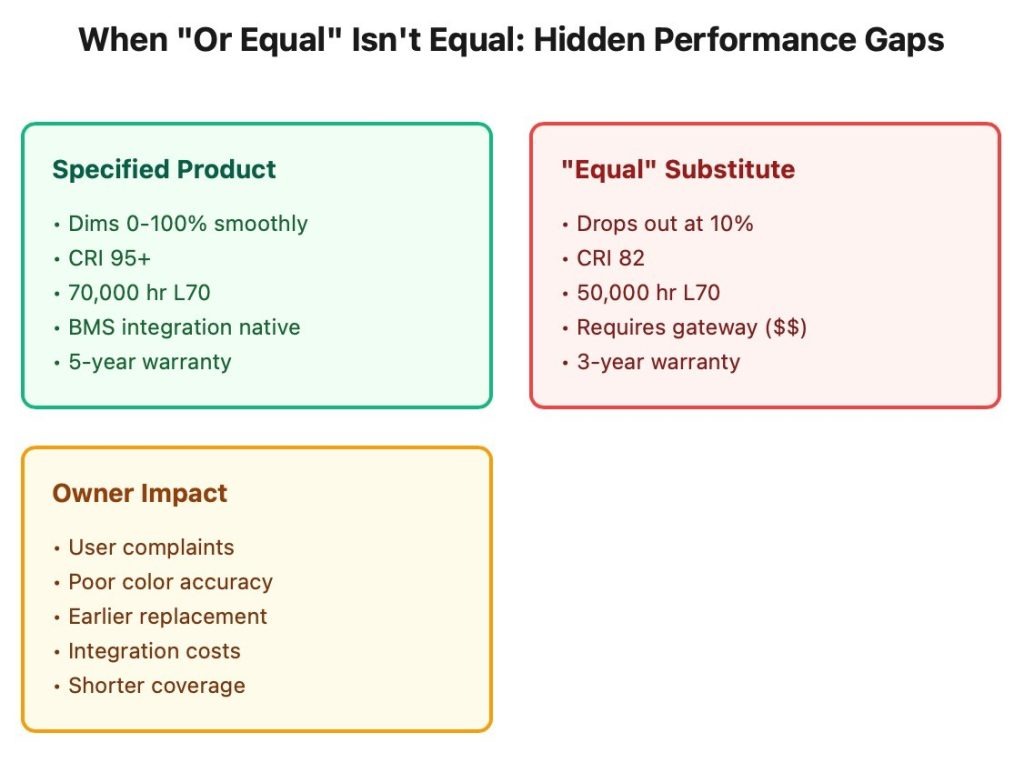

No two products are truly equal — that could introduce patent violations. Yet specifications routinely list multiple manufacturers as “equals,” creating a potential for a race to the bottom where the lowest-cost option wins regardless of performance differences.

One LED luminaire may have superior color rendering that makes merchandise appealing in retail environments. Another might offer better thermal management for high-temperature industrial applications. A third could provide dimming that drops smoothly to one percent, while a cheaper “equal” drops out at 10 percent with visible strobing —devastating for healthcare environments where visual precision matters.

Controls amplify these differences exponentially. Integrated automation systems managing lighting, HVAC, and building systems aren’t commodities. User interface design, programming complexity, sensor accuracy, and integration protocols vary dramatically. When specifiers write “or equal,” they’re forced to include products they’d never select independently. The specification becomes a menu of options rather than a prescription for success.

Value Engineering: Specification Vandalism

Value engineering has become construction’s most-abused term. The lighting industry currently faces cost pressures from tariffs up to 25% on goods from Mexico and Canada, plus an additional 10% on Chinese imports. But value engineering and cost cutting aren’t synonyms.

True value engineering happens during design development when teams can meaningfully evaluate alternatives. When contractors submit value engineering proposals during bidding, they’re not optimizing value — they’re optimizing their margin.

Consider a typical scenario: Specifications call for networked digital lighting controls with occupancy sensing, daylight harvesting, and building management integration. The value engineering proposal substitutes basic on/off control and manual dimming. The contractor saves $50,000 upfront. The owner loses $20,000 annually in energy costs and spends $15,000 addressing user complaints. Over 15 years, that “value engineering” costs the owner $475,000.

In industrial facilities, the consequences are starker. Value engineering a high-bay LED system from 150 to 75 foot-candles might save $30,000, but increased workplace injuries and defect rates can cost millions in liability and lost productivity.

Current Pressures: Tariffs and Market Volatility

The commercial and industrial lighting sector navigates unprecedented cost volatility. New tariffs raise prices on lighting goods while market uncertainty makes it harder to predict costs and lock in pricing on long-lead items. This environment creates enormous pressure to compromise specifications.

But cost pressure and specification integrity aren’t mutually exclusive. Smart teams address tariff impacts through early procurement, transparent budgeting, strategic specification focusing on performance requirements, and lifecycle analysis evaluating true costs including energy consumption and maintenance. The worst response to tariff pressure is reflexive value engineering creating long-term costs far exceeding short-term savings.

The Substitution Game

Product substitutions represent another pressure point where specifications hemorrhage value. Evaluating equivalency in lighting and controls requires deep technical knowledge. Is a proposed LED luminaire truly equivalent if it has the same lumen output, but different spectral distribution? Does the control system communicate via the specified protocol, or will it require proprietary gateways creating integration costs and maintenance nightmares?

Current tariffs have impacted fixture housings, brackets, LED heat sinks, and casings, creating price volatility that encourages substitution requests. But cost pressure doesn’t justify compromising performance. Tight specifications with strict performance criteria can limit substitution chaos, but they falter when specifiers lack institutional support to enforce them.

Why Contractors Should Champion Specifications

Supporting rigorous specifications serves contractors’ long-term interests:

Liability Protection: Following specifications protects you. Deviating – even with approval –transfers risk. If that value-engineered system fails to meet energy codes, who’s responsible? The contractor who proposed the change.

Competitive Advantage: Expertise in specified systems differentiates you from commodity bidders. You’re delivering sophisticated building systems, not just installing fixtures. That expertise commands premium pricing and builds repeat relationships.

Fewer Change Orders: Clear specifications reduce ambiguity, disputes, and rework. The most contentious, least profitable projects have vague specifications inviting interpretation.

Owner Satisfaction: Delivering what was specified creates satisfied clients providing referrals and repeat business. Short-term gains from value engineering rarely outweigh long-term reputation costs.

The Distributor’s Role

Electrical distributors bridge manufacturers, contractors, and specifications. When contractors request something “like” the specified product, but cheaper, you face a choice: enable the race to the bottom or educate about consequences.

With tariff uncertainty driving higher LED lighting prices, distributors face pressure to offer cheaper alternatives — but your expertise has never been more valuable. Owners need trusted advisors explaining why specified products justify their cost or identifying legitimate substitutes meeting performance requirements without compromise.

This means sometimes refusing substitution requests that don’t meet specifications, investing in training on technical differences between systems, and partnering with specifiers to develop competitive yet clear specifications.

What Owners Must Understand

You get what you specify. When you hire lighting designers or controls engineers, you’re paying for expertise manifesting in specifications. When specifications get compromised through casual substitutions and shortsighted value engineering, you’re undermining your own investment.

The timing of lighting and controls specifications makes them vulnerable to budget pressure. But vulnerability doesn’t justify treating them as optional. If your project is over budget, address it honestly through scope reduction or additional funding — not specification erosion delivering substandard performance.

Demand your design team enforce specifications. Question value-engineering proposals that seem too good to be true. Tariffs worsen budget pressures, but temporary cost challenges don’t justify permanent performance compromises.

The Bottom Line

Every compromised specification reinforces a culture devaluing expertise and rewarding the lowest common denominator. We tell owners their hired professionals don’t matter, tell contractors craftsmanship is less important than price, and create buildings that underperform and cost more to operate.

The CSI structure placing lighting and controls late in specifications creates vulnerability, but vulnerability doesn’t justify capitulation. Tariff pressures create cost challenges, but temporary disruptions don’t justify permanent compromises.

Specifications translate design intent into buildable requirements. They protect owners from false economy and establish standards elevating our industry rather than commoditizing it.

The question isn’t whether we can afford to maintain specification integrity — it’s whether we can afford not to. Every compromised specification makes it harder to deliver the high-performance facilities our economy depends on.

The next time you’re tempted to accept that substitute or approve that value-engineering proposal, ask: What would the owner choose if they truly understood the implications? That’s the standard we should hold ourselves to — not what we can get away with, but what serves the people who trusted us with their project.

About the author

Geoffrey Marlow is President of Marlow Advisory Group, providing strategic consulting to lighting industry professionals and manufacturers.

Additional articles by Geoff Marlow

Why Lighting Reps Carry So Many Lines: Understanding the Multi-Line Strategy in Today’s Market

AI in the Lighting Industry: Today’s Reality, Tomorrow’s Opportunity