Why Does Industrial LED Lighting Require Robust Components?

July 8, 2020

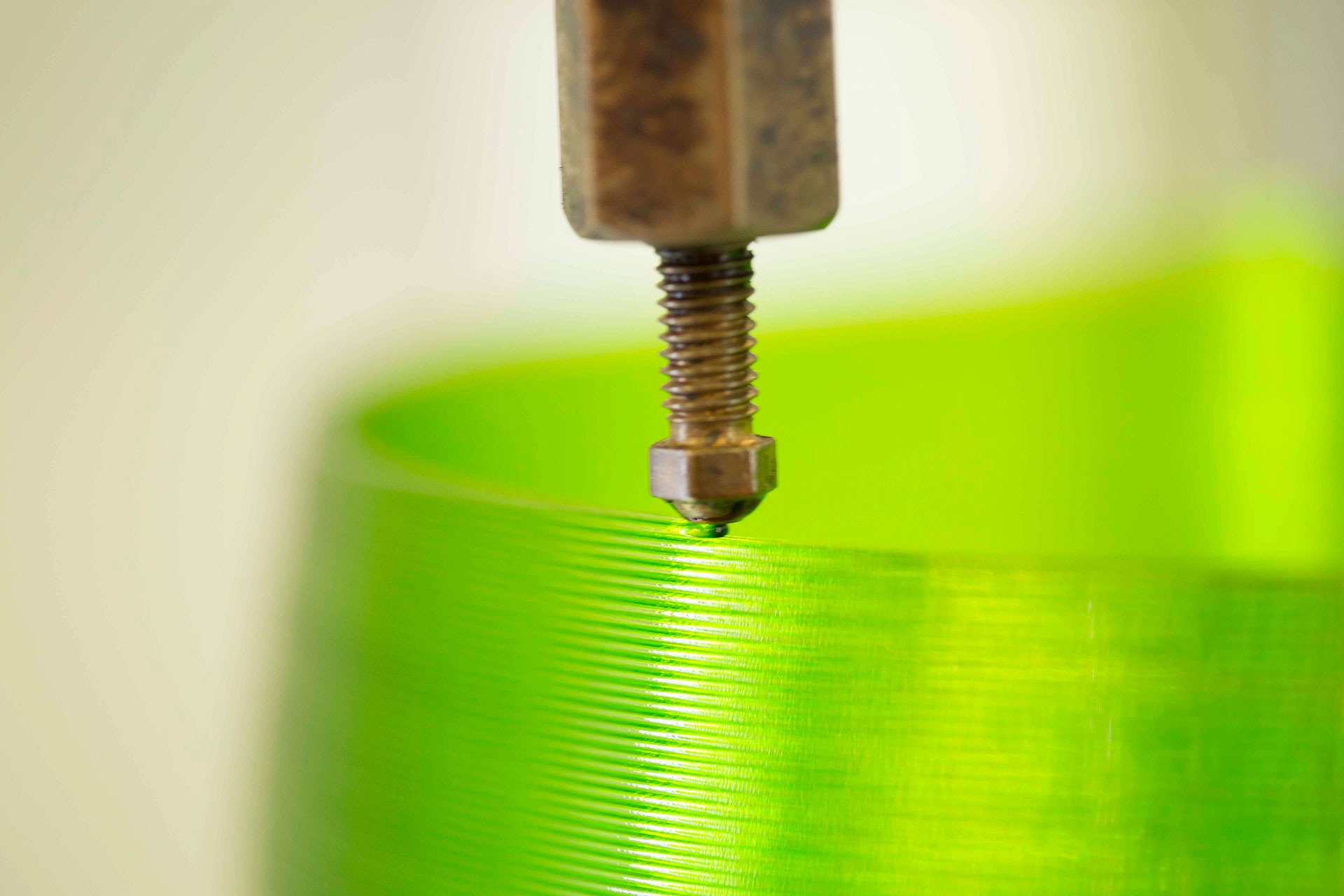

Industrial environments from warehouses to manufacturing plants are more harsh than typical work environments such as commercial office space. Temperatures can be extremely cold or hot because of a lack of heating, ventilation and air conditioning, and equipment may be partially exposed to the elements. In addition, there may be heavy equipment and machinery that causes voltage spikes and vibration, or other environmental conditions such as humidity and dust that affect equipment performance and long-term reliability.

Luminaires for industrial settings need to be built to withstand these harsh conditions. They must be able to operate efficiently and support the safety and productivity of both the occupants and machinery in the facility. The quality and specifications of the LED driver installed in the luminaire is critical because it determines how well the luminaire will perform from an energy efficiency, light quality and maintenance perspective.

Energy efficiency

LED technology and building code requirements have resulted in a substantial savings in the amount of electricity used for lighting in many industrial spaces. LED lighting operates at significantly lower power consumption levels as compared to fluorescent or high intensity discharge (HID) technologies. However, there is still room for improvement particularly in those industrial warehouses and manufacturing facilities that operate on a 24/7 schedule.

With advancements in lighting controls, LED luminaires can take advantage of wireless sensors and controls to further optimize a lighting system. Leveraging sensors, dimming strategies, and natural light can further reduce energy consumption while still maintaining optimal levels of light in the space. Some industrial LED drivers include an auxiliary output for directly powering fixture-integrated sensors and controls.

High Quality of Light

Due to the high ceilings in industrial environments, luminaires must operate with a high light output to illuminate work areas brightly and evenly so that employees, as well as the machinery, can work safely and efficiently. Additionally, the quality of light, including flicker, dimming performance (true 1% dimming) and DIM-to-OFF, can be critical in some environments such as food processing plants, hospitals, stadiums, schools and factories.

Many industrial facilities leverage scanning systems for real-time visibility of inventory. Where scanning systems are applied, the lighting must not only be bright, but its quality must also be high, so that these systems, most of which are very sensitive to ambient light, can work properly. Industrial LED drivers ensure a high quality of light by operating at high switching frequencies resulting in low output flicker and stroboscopic effects even at minimum dim levels. This means that negative effects on scanner and video surveillance systems can be prevented – at any dimming level.

Reliable Light Output Across a Wide Temperature Range

LED driver data can tell you a lot about the performance level of a luminaire as well as how much ‘life’ remains in the luminaire. Early detection can mean simpler and less costly repairs. For example, the LED fixture will start to go through lumen depreciation over time, but a quality LED driver will compensate for this depreciation by producing a steady state of measured light output across the entire lifetime of the fixture. Adjusting the current as the LED begins to fade effectively maintains 100% light output over life.

Additionally, luminaires are usually installed at ceiling heights of 25 feet or higher in industrial spaces. Addressing any problems with lighting fixtures can require not only skilled personnel but often special equipment. This makes maintenance challenging and costly especially if machines or production lines must stop while the maintenance is done.

It is critical that luminaires in this environment are highly reliable and energy efficient. A high-quality luminaire requires a reliable LED driver which can operate in harsh environments consistently across a wide ambient temperature range (-40C to 55C) and support low touch maintenance programs.

OPTOTRONIC Industrial LED drivers are highly reliable, energy efficient, designed to operate in harsh industrial environments and carry a 5-year warranty.

To learn more, download the datasheet HERE.