Halco Slim Downlight Redefines Retrofits with Push‑Lens Simplicity

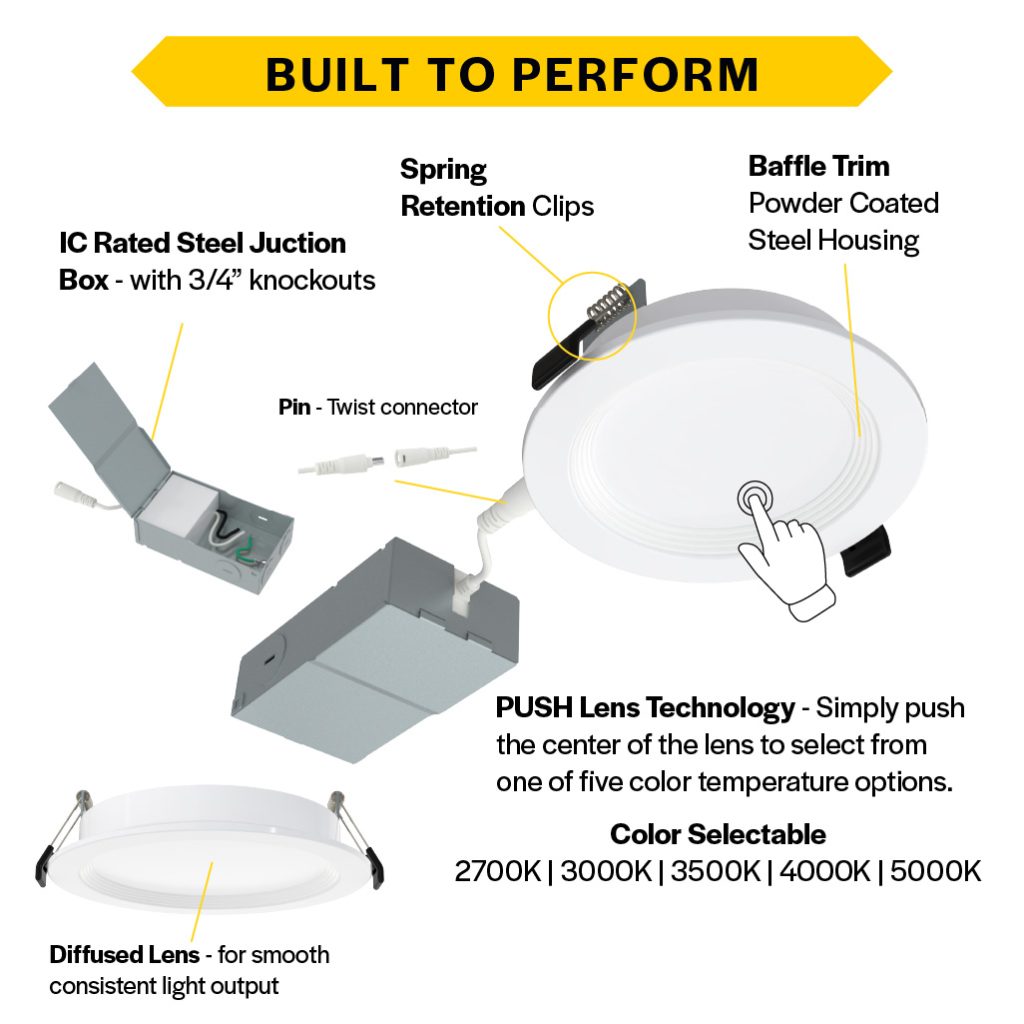

Halco Lighting Technologies is making recessed lighting upgrades faster and more flexible with the Push Lens Slim Downlight (SDL), a low‑profile, canless fixture built for tight plenums, quick retrofits and new construction installs. Instead of removing trims or accessing hidden switches, contractors can adjust color temperature right from the ceiling by pressing the center of the lens. It’s a small detail that eliminates guesswork and keeps projects moving.

The SDL lineup includes 4‑inch (750 lm) and 6‑inch (1100 lm) models, each delivering 90+ CRI and smooth Triac dimming at 120V. A remote driver junction box simplifies installation in shallow ceilings and removes the need for traditional cans. Because of this, the fixture is ideal for multifamily, hospitality and light‑commercial environments. With five selectable CCTs—2700K, 3000K, 3500K, 4000K and 5000K—the SDL adapts easily to mixed‑use spaces or last‑minute design changes.

To support real‑world field conditions, the Slim Downlight is also wet‑location rated, JA8 compliant, and engineered for long‑term performance with L70 > 50,000 hours and a 5‑year warranty. Smooth and baffle trim options give specifiers flexibility, while the nonconductive housing helps streamline code compliance in damp areas.

Technical Highlights of the Halco Slim Downlight

- Selectable 2700K / 3000K / 3500K / 4000K / 5000K via push lens

- 90+ CRI for accurate color rendering

- 750 lm (4″) or 1100 lm (6″) output options

- Slim, canless profile with remote driver junction box

- Wet‑location rated for showers and covered outdoor spaces

- Triac dimmable, 120V operation

- L70 > 50,000 hours and 5‑year warranty

Halco’s Push Lens Slim Downlight is built for crews who want fewer SKUs, fewer callbacks and more control at the ceiling plane. It’s a practical, adaptable recessed solution that keeps ceilings clean and installation timelines tight.

Learn more about the Halco Push Lens Slim Downlight.